Typical problems

The master data management in SAP is a key process ensuring the effective work in the system. Master data, along with customizing data, is the driver for all transactions used to record business events in SAP. It would not be possible to create purchase orders, if material master records representing purchased raw materials and vendor master records were not defined in the system. Similarly, it would not be possible to sale finished products on the basis of sales orders, if there were no material master records representing those products and customer master records. Master data plays a fundamental role in all modules and functional areas of the SAP system.

Why then, is it not given due attention, especially during the implementation project? The issue of master data management during the implementation project is often pushed to the margins; after all, operational or accounting processes are more important. Result: master data is not maintained on time, which leads to unwanted downtimes, or is maintained, but incorrectly, causing the need for reversal and re-entry of documents. Well-maintained master data allows you to avoid a lot of unnecessary trouble and frustration when working with the system. Proper maintenance of master data, however, requires, firstly, an appropriate process model for master data management, and secondly, a proper tool to support this process.

All for One MatFlow

In the past few years, we worked for many companies that struggled with master data issues, especially in the area of material master records. We have developed solutions in this area, resolving this problem both from an organizational and system perspective. Examples of issues we encountered include master data uploaded directly from the Excel file embedded in SAP GUI, the process of preparing the material master record after the release of the CAD drawing in the DMS, replication of a material master record to other systems via IDOC, etc.

Out of our experience and successful projects emerged a picture of processes and tools that regardless of the company and industry solve the problem of incomplete or inaccurate material master data. The result is a standardized product that allows you to solve a number of issues related to the material master data management. All for One MatFlow is a solution containing template processes for creating / changing material master data that are implemented in SAP Business Workflow and supported by relevant non-standard applications. Through the use of SAP Business Workflow, the tool automates the work on master data, which ensures that all required process steps are executed at the right time, in the right order and by the right people. All processes implemented in the tool may be monitored from standard and non-standard reports.

Material requisition – centralized process

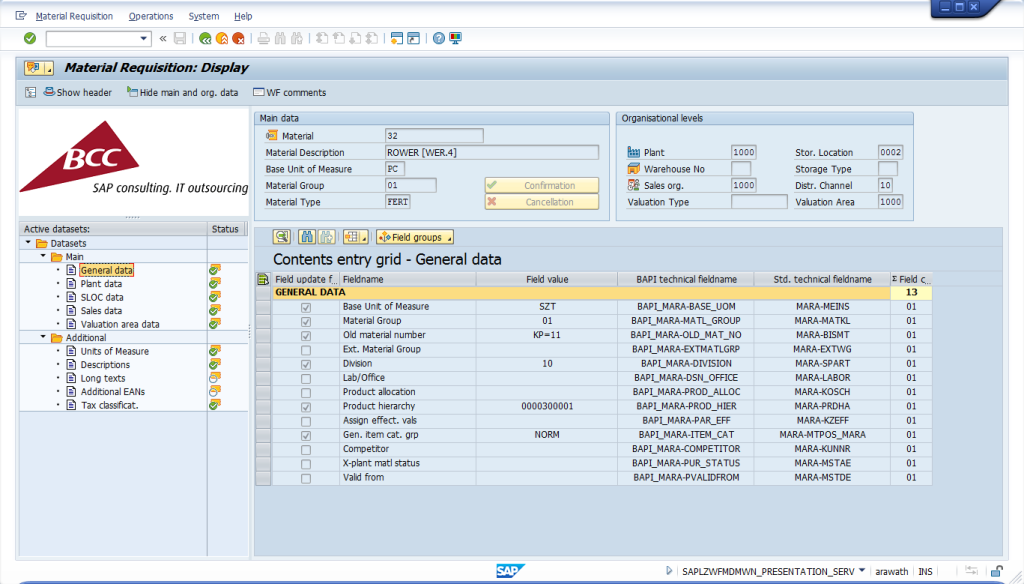

The main component of All for One MatFlow is an application representing a material requisition which is a non-standard system document (see the screenshot below). A material requisition can capture the need for the creation, extension or change of material master data in a structured manner, fully consistent with the standard data model of a material master record, without the need for an immediate change in standard database tables. Each employee may at any time request the creation of new data or corrections to the existing data, not exposing themselves to a situation in which the change of data on the actual material master data record could lead for example to errors in the system documents that record certain events.

Material requisition – main component of All for One MatFlow

The existence of a document having the character of a request to perform certain actions implies the existence of a process in which the request can be processed. In reality, processes based on a multitude of different requests constitute the daily life of an organization: leave requests accepted by a supervisor, purchase requests processed by purchasing departments, etc. It is no different in the case of master data. Our experience shows that the establishment of a dedicated organizational unit responsible for master data, or at least a full-time position of master data specialist, leads to the improvement in quality of master data, and consequently smoother and more efficient operation of the system.

A template process model implemented in All for One MatFlow supports exactly this kind of flow. Employees from different departments request changes (creation of new records / change in existing ones) in a material master data record using a material requisition. The requisition is sent via workflow to a specialist(s) who may accept or reject it (giving reasons for their decision), and most importantly, they can correct and / or supplement it prior to acceptance. It should be emphasized that acceptance of the requisition triggers a fully automatic entry of material master data record to the standard tables by calling the SAP API interface (which guarantees data consistency).

All for One MatFlow is not just a tool, another custom application in the system – we offer a work philosophy, whose primary feature is separation of authorizations and responsibilities of persons who interact with the material master data record (a division to requesters and experts). Therefore, this process will also work well in shared services centers that can perform not only financial and accounting processes, but may also be responsible for the central management of master data.

Material requisition – decentralized process

The described template process model emphasizes the role of centralization in the management of material master data. Our experience shows that this approach leads to good results, especially in large corporations / holding companies, which often have a separate shared services center or an organization / group of people completely responsible for the material master data.

However, there are companies (typically smaller companies from the SME sector), which in the context of material master data management act in a way that can be described as decentralized. The development of standard transactions for managing a material master data record indicates that SAP, while designing its flagship product, SAP ERP, proposed such a model for companies. MM0x transactions are built in such a way that fields are grouped according to functional areas: sales master data, purchasing master data, warehouse master data, quality control master data, accounting master data, controlling master data, etc. Such a structure of transactions in a natural way imposes a division of work according to the functional structure of the organization. Thus, many companies have spontaneously adopted this approach in the material master data management.

The objective to develop a complete material master record cannot be achieved by performing an isolated task assigned to one department (I do not mean a dedicated specialized organizational unit, but rather a typical organizational unit, such as purchasing, sales, etc.). The maintenance of a material master record is a process performed by people from different departments across a functional structure.

All for One MatFlow can support this decentralized process as effectively as the centralized process. A material requisition is a data medium necessary for the creation / change of material master records and may be forwarded automatically using workflow mechanisms. It is also unnecessary to create the data required by the requester in full – the requisition can be sent e.g. only with basic data, such as organizational units or descriptions. Consequently, the material requisition may “journey" through many departments (using workflow) where workers can fill in the data for which they are responsible – roughly in accordance with the functional division. The last person in such a process accepts the requisition, which will generate a complete set of data in the standard material master data database tables.

Centralized and decentralized material requisition flow – comparison

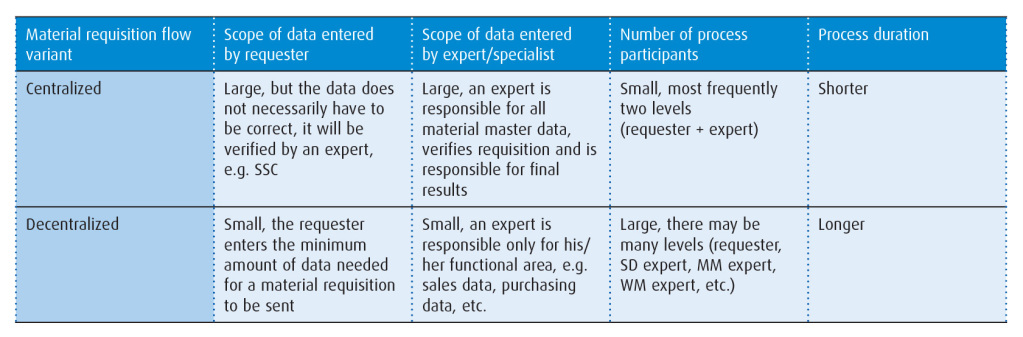

In summary, the key application of All for One MatFlow, which is a material requisition, and workflow mechanisms can successfully support both centralized and decentralized model of material master data maintenance process. In both cases, the greatest advantage of the solution is that all work is done in absolute isolation, on the material requisition, and the material master data record is supplied with a complete set of data reliably maintained by specialists, shared services center, or simply by employees of various departments. The table below presents the features of both variants of material requisition flow implementation: centralized and decentralized.

All for One MatFlow implementation variants – centralized and decentralized material requisition flow

Complete material master data maintenance process

The created material master record is by no means the end result of the process of creating a material in SAP, but it is the beginning of the process, in fact it is its first step. Each material master maintenance process in SAP can be divided into three consecutive phases:

- Creation of a material master record

- Creation of other master data objects associated with the material master record

- Notifying the process stakeholders of the result.

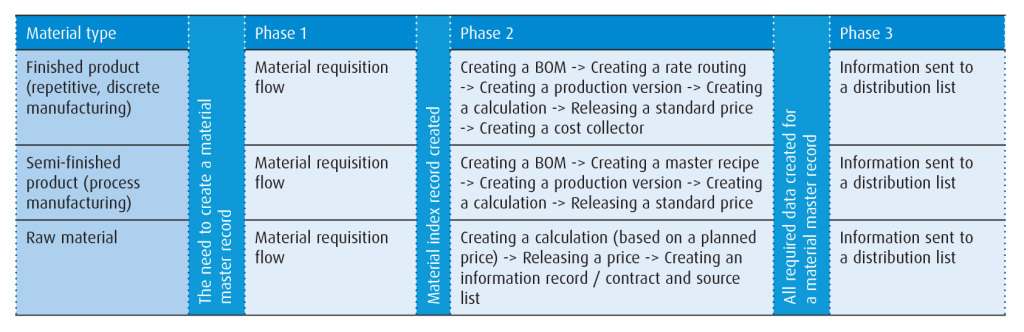

Depending on a material type (finished product, semi-finished product, raw material, packaging, etc.), the scope of fields maintained in phase 1 may differ, but above all the scope of objects to be created in phase 2 is different. In principle, phase 2 can be seen as a sub-process, as it may consist of several steps. For example, a finished product / semi-finished product require the creation of a bill of materials, routing (discrete manufacturing) or recipe (process manufacturing), etc. A raw material does not require any bill of materials, but may require a purchasing info record to be created.

All for One MatFlow has been designed to support the master data maintenance process in accordance with the above scheme. Phase 1 (creation of a material master record) is always carried out as the already described material requisition flow (centralized / decentralized variant). In phase 2, standard transactions are used to create objects related to a material master record. Phase 3 comes down to sending e-mails to a distribution list assigned to the process. All three phases are implemented in All for One MatFlow as workflow templates.

However, the final implementation of phase 2 depends greatly on the business activity of the company and the way in which the activities carried out in the company have been mapped to activities in the SAP ERP system during its implementation. Therefore, in this context, All for One MatFlow should be considered in some sense as an intermediate product. The solution contains a customizing table, which is used to determine different workflow templates (for phase 2) depending on a material type and the action requested on a material requisition (new material master record, change in an existing material master record, etc.)

In the standard version, All for One MatFlow includes workflow templates developed on the basis of the experiences of SNP, which can be adapted in whole or can be used as a reference for the creation of new, customer-specific workflow templates. The table below presents examples implemented in All for One MatFlow.

Examples of end-to-end processes for material master data maintenance implemented in All for One MatFlow according to the presented division into three phases

Master data project card

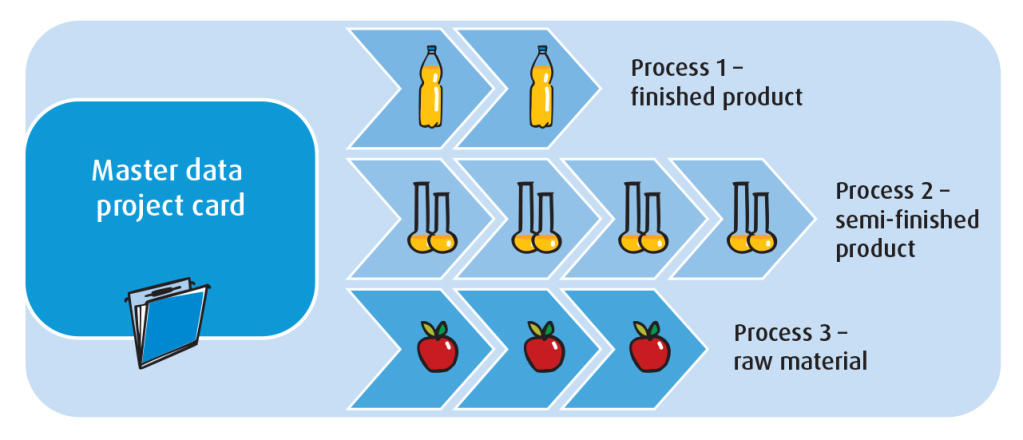

The last component of All for One MatFlow is the application representing another non-standard system document – a master data project card. In principle, a project card serves three purposes. Firstly, it is used for the registration of projects in which material master data is created, such as implementation of the production of a new finished product, change of an existing product image which requires the creation of new packaging, etc. Secondly, depending on the project type, it is used for the automatic identification of persons responsible for creating material master data in the project and automatic notification of these persons using workflow mechanisms. And thirdly, the card is designed to monitor material master data creation processes within the project it represents.

The master data project card complements the tools described earlier: a material requisition and workflow templates. Integration of the card and material requisition is achieved simply by entering a card number in a relevant field on a material requisition. Then, the workflow process covering the previously described three phases of master data creation is visible on a project card.

For one project card, N processes can be started for different materials, allowing monitoring of work progress within the project. In addition, the card allows collecting textual information about the project and binary attachments, such as graphics, XLS files, etc. The diagram below symbolically shows how the card groups run workflow processes according to a project.

Grouping of workflow processes in the master data project card

All for One MatFlow implementation project

All for One MatFlow is a powerful tool, therefore, an implementation project bearing the signs of a rollout is required for launching it. If we treat the product version available “out of the box" as a reference model, its launch should be preceded by a Fit & Gap analysis.

We assume that the core of the solution, i.e. material requisition and project card applications, along with the philosophy of work based on the SAP Business Workflow technology will be adapted in its entirety. We anticipate, however, that the implementation changes will be effected primarily in the area of workflow templates (earlier described phase 2). A fit & Gap analysis should show these differences.

Examples: In the customer’s environment, the material master record is replicated to another system when it is fully maintained in SAP ERP. In this case, the gap will indicate that we should add a step with the task calling the transaction which sends an IDOC to the indicated system to a standard workflow template number XYZ. The analysis should also answer the following questions: what material types are used in the company?; what additional data is required for each material type?; are there any non-standard fields on a material master record that should be added to a material request?; what groups of fields on a material requisition should be hidden, depending on a material type?; who will process specific workflow tasks?; what master data project types exist in the company?

Master data comprehensively

All for One MatFlow was developed based on the experience gained during the implementation projects conducted in companies that are leaders in their industries. Business processes implemented in the solution can therefore be considered good practices in the management of material master data. The tools contained in All for One MatFlow support these practices in the best possible way.

Basing the entire solution on the SAP Business Workflow technology leads to excellent results in terms of coordination of work when creating and changing material master data and other related data: the tasks are automatically forwarded to the right people, in the right order, always according to the designed process model. Moreover, the use of the SAP Business Workflow technology offers great possibilities of process tracking, monitoring of work progress and workload of each individual. In summary, All for One MatFlow allows above all the comprehensive organization of work on material master data in one consistent model, and well-organized work leads to good results – in this case to complete, error-free, on-time developed material master data and the related data.